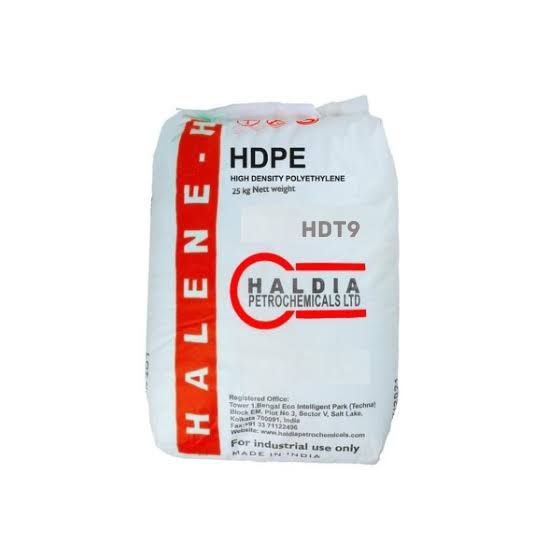

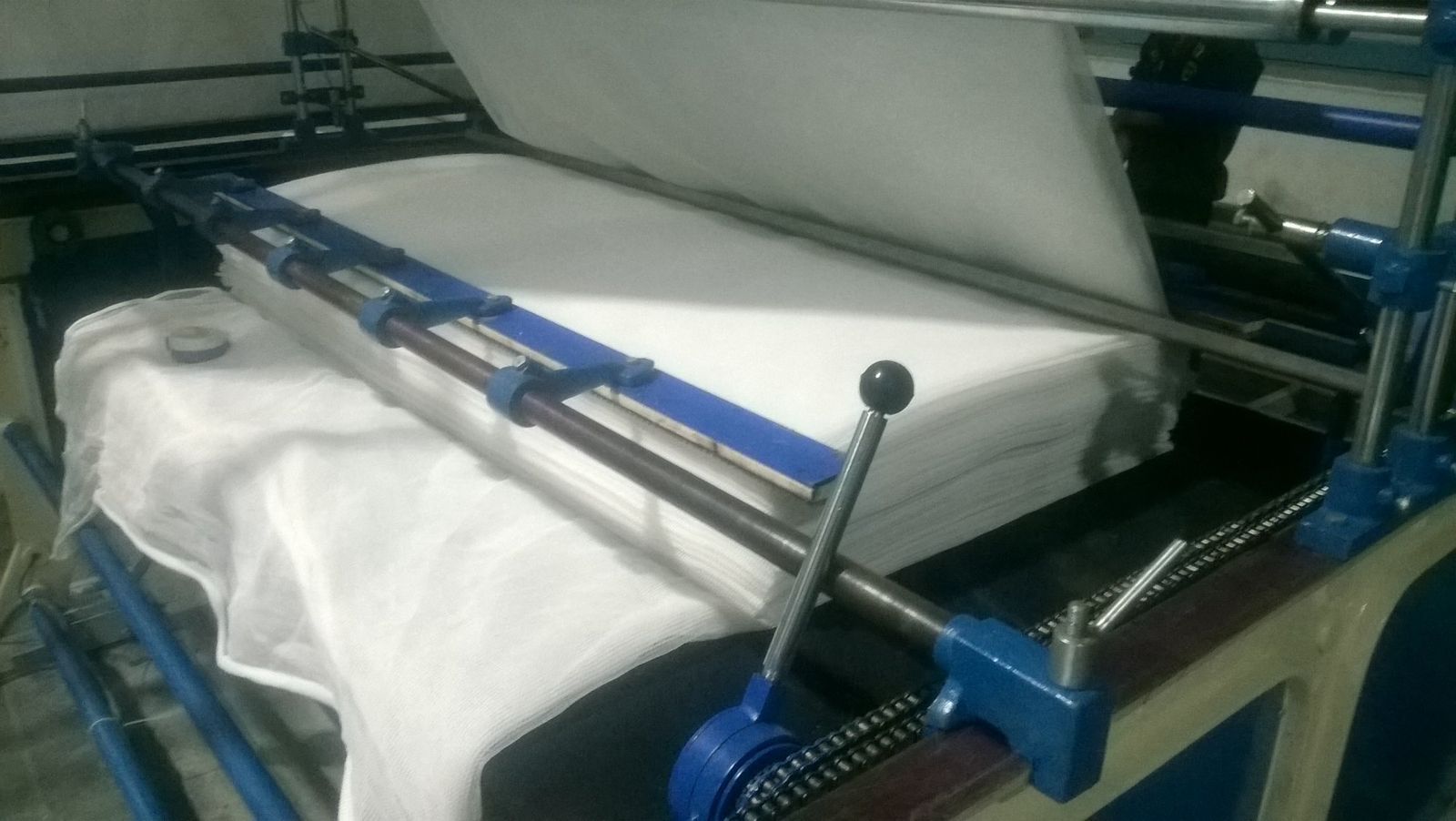

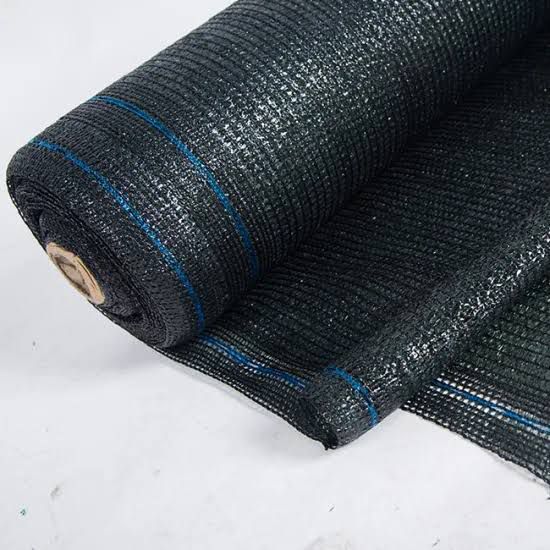

From Material Selection to Finishing

At Umang Plastic Fabric, we follow a carefully designed, proven workflow to achieve consistent quality and long-lasting performance. Each stage is optimized for strength, UV stability, and uniform mesh construction, ensuring our nets look premium and perform reliably across seasons.